-40%

Supertech Valves STD Size Ford 2.0L Focus Zetec ST SVT ZTS ZTW ZX3 ZX4 ZX5 USDM

$ 142.03

- Description

- Size Guide

Description

Go Race Parts presents...Our special on Supertech Performance Valves & Components!

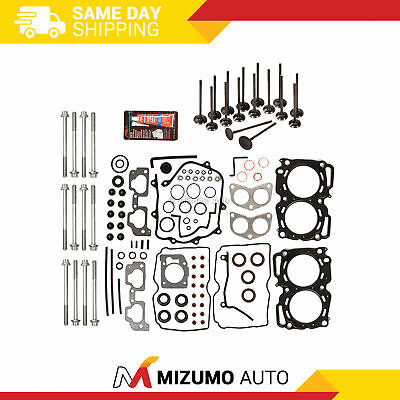

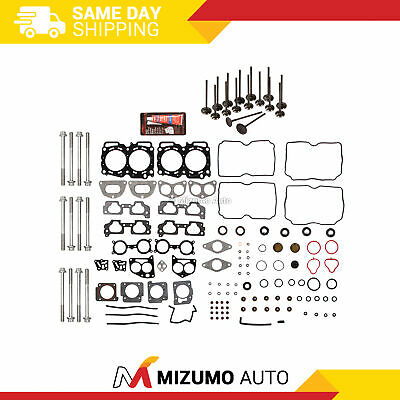

This listing is for a complete set of 16 STD Size Supertech Black Nitride Valves for all

2002-2004 Ford Focus 2.0L

applications

These 200 series valves work well as OEM replacement valves, also good for stock to mild street applications.

This listing includes Supertech part numbers:

FIVN-1035 x 8 (intake)

FEVN-1035 x 8 (exhaust)

Head Diameter: 32.0mm (intake)

28.0mm (exhaust)

Stem Diameter: 6.035mm (intake)

6.012mm (exhaust)

Valve Length: 97.10mm (intake)

96.70mm (exhaust)

Material: Black Nitrided

BLACK NITRIDE:

This is a hardening treatment that even though it is not widely used as the chrome coating, it has several benefits and is becoming very popular, mainly for European and Japanese applications.

The microhardness is higher than the stainless steel base material, keeping good ductility beneath the hard nitrided layer (microhardness is 800HV minimum).

Surface finish is smoother than with chromed stems, having less friction between stem and guide.

Valve seat surface is harder with the nitrided layer, lasting longer with lead free fuels, alcohols, nitro or other "explosive" mixes. Matches any kind of seats (nodular iron seats, steel powder metal seats, hard aluminum-copper seats or beryllium copper seats).

Higher rpm's engines take full advantage of all previous features. The higher the engine speed the bigger the power loss due to internal engine friction! The black nitride layer reduces this power loss due to less valve-guide friction.

The nitrided layer is adhered to the base material at a microscopic level, so does not "flake" or break when the valves bend due to impacts with the pistons.

The Black Nitride applies to the whole valve while the chrome coating is only applied to the stem.

All valves are swirl polished, have stem undercut and a hardened tip.

Product info

We apply more than 30 years of experience in the development of each and every Supertech racing valve we sell. Combine this experience with state of the art equipment such as ultrasonic tests, x-rays, laser measurement equipment, and applications like computerized Finite Element Analysis (FEA) and it is no wonder why supertech has some of the best performance products on the market.

While this is more than most manufacturers we don’t stop there. We also do extensive testing working very closely with many of today's top engine builders in order to

continuously improve our products. All of this is meant to insure Supertech's industry leading reputation for high flow rates, durability and uncompromising quality.

Higher Flow Rates

Our valves are not finished from generic blanks rather they are specifically designed for each and every application. We work relentlessly, testing and researching every aspect trying to improve the air flow of our designs.

Durability

With every valve design we strive to maximize durability through higher fatigue resistance and tensile strength. Each valve tip is hardened beyond 52HRc.

Stem Super finishing

In 2006 we introduced our stem Superfinishing as a standard addition to all of our valves and provided it at no additional cost. When our Superfinish is combined with our Black Nitrided valve it reduces the surface roughness to 1/3 of our chrome coated valve. The end result… unsurpassed performance and durability.

Strict Dimensional Tolerances

It's unlikely you will find any of our competitor’s valves with stricter dimensional tolerances than our Supertech valves. Combine that with finished seats with equally strict run out tolerances and you won’t find a better sealing, better performing and easier to install solution anywhere!

**** International customers are welcome ****

For any questions regarding this listing please do not hesitate to contact us! We pride ourselves in the offering the best pricing and customer service on the internet!